Here are seven things you can do to keep your diesel engine working better and longer, from Skipper Tips. Read on:

Do you go through a step-by-step inspection of your engine before you hit the “start” button? Make sure you check these seven vital components before you do. This could add years of life to your boat’s diesel workhorse.

1. Oil

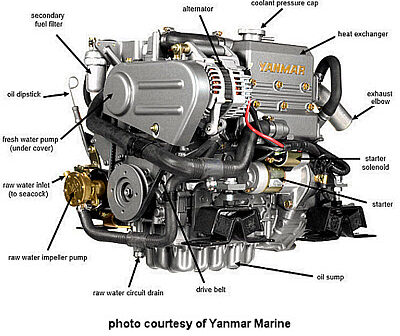

Use this double-dip technique. Pull the dip-stick out and wipe it off. Push it back in all the way so that it gets to the bottom of the oil sump. Pull it out and look at the oil color. It should be black (brown or streaked indicates water in the oil). Smear the oil on your fingers and shine a light onto it. Granules signal internal metal fatigue. Address any problems right away.

2. Transmission fluid

Yes, it’s a pain to check transmission fluid, but repairs are costly if you don’t. Make sure to check the fluid level twice for accuracy. Most transmission dip-sticks screw into the engine. Unscrew the stick and pull it out. Wipe it clean, then reinsert it to where the threads just touch the housing (do not screw it back in until you check the level). Pull it out, check the level, and smell the fluid. A burned odor means your transmission needs service right away.

3. Coolant cap and fluid level

Remove the header tank cap, turn it over, and check the gasket. Worn cap gaskets are unable to provide a tight seal. Replace the entire cap. Otherwise, you will lose coolant. This could cause the engine to overheat and result in internal damage. Stick your finger into the header tank (cold tank only!). Keep the fluid level close to the top of the fill.

4. Belts and hoses

Depress the drive belts. Adjust or replace any belt that has more than 1/2 inch of play. Feel hoses (cold only) for softness. Look for cracks or abrasion. Replace defective belts and hoses right away. Carry spares aboard as part of your spare parts kit.

5. Stuffing box (packing gland)

Look for excessive leaks at the shaft packing. More than one boat has sunk on a mooring or at anchor from a leaking stuffing box. Two or three drops a minute provide lubrication, but more than that tells you the nuts are too loose or the packing material has worn. You will need two over-sized wrenches to tighten the nuts. If it still leaks, replace the packing material.

6. Raw water seacock and exhaust

Make sure the raw-water seacock handle lines up with the raw water hose. This opens the valve to allow cooling water to the engine. After you start the engine, check the stern exhaust tube for a steady flow of water. Blockage often points to a clogged raw water filter or an object trapped against the outside raw water intake.

7. Test battery cables

Cables loosen when the boat pitches, rolls, or vibrates at sea. Check the connection at each battery terminal and on the side of the engine.

Add years of life and save big money in repair costs with these seven simple inspections. Your sailboat diesel will reward you with smooth, reliable, starts-every-time service for many sailing seasons to come. Read more: http://skippertips.com